How does Cottony Work

Cottony, with its vast experience in this industry provides the best quality output with the usage of highly advanced machineries and skillful labours with an efficient supply chain management to look deep into every process of manufacturing.

1Yarn

Choosing the right fibers is crucial for quality and durability of the end product. Factors to consider include tensile strength, elasticity, texture, and colorfastness, as well as intended use. Natural fibers offer breathability, while synthetics provide durability. Sustainable options like bamboo and organic cotton are eco-friendly. Consideration of these factors ensures that fibers are best suited to achieve desired results.

- Cotton

- Organic Cotton

- Modal

- Viscose made from Bamboo

- Viscose

- Elastane (Spandex)

- Nylon

- Polyester Filament

- Polyester Staple

2Knitting

Fabric construction involves weaving fibers or yarns to create a flexible and durable material. Different fibers and weaving patterns can create various textures and strengths. Chemical treatments and dyes can enhance properties. Quality control is essential.

- Fleece

- French Terry

- Jersey

- Interlock

- Pique

- Mesh

- Melange

- Viscose blends

- Cotton blends

- Polyester Blends

3Dyeing

Dyeing units can imply Soft flow Dyeing, Airflow Dyeing and other major dyeing techniques.

4Compacting

Our compacting process provides fantabulous finishing for the freshly printed fabrics which illuminates the quality of the fabric, making it free from wrinkles.

5Printing

Printing units performs Phthalate free printing, Nickel free printing, PVC free printing, CMYK printing, Reactive printing, Discharge printing, Flock printing, Hi-Density printing and all Pigment printings.

6Embroidering

Embroidery units apply Applique embroidery, Sequence embroidery and all other types of embroidery processes.

7Cutting

Highly skilled employees and well fabricated machines get together and bring out precise elements for the garments.

8Sewing

Modernized sewing systems with qualified and experienced employees with high professional machines are used for crafting the fabric.

9Trimming & Checking

Advanced Air-operated machines with under-thread Cutter are utilized for cutting and trimming the unwanted remaining of the sewing process.

10Ironing

Vacuum-press ironing machines are used for removing wrinkles with ease and iron them to provide a better appearance and perfect finishing.

11Packing

The garment is checked completely before packing process. The garment is tagged and finally packed into a complete product.

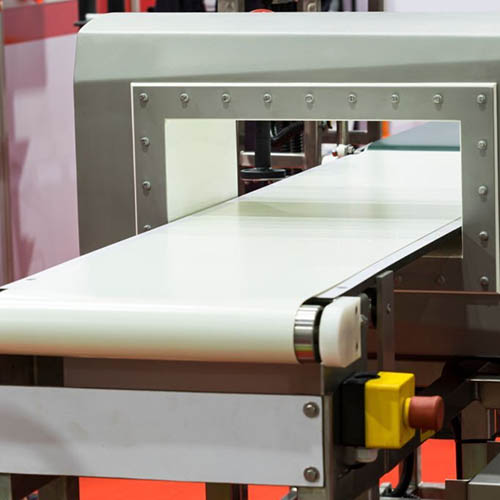

12Metal Detecting

Completely mechanized, Needle check metal detector machines are used for detecting the metal contamination from the garments.

13Carton Box Packing

Packed in sturdy carton boxes to ensure secure delivery and safe storage. We use high-quality packaging materials for superior protection.